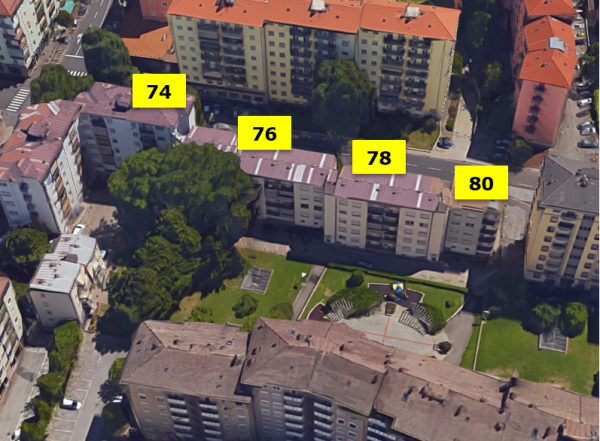

Europa Novacella Quarter - VIA PALERMO 74-76-78-80

Name and address

Europa Novacella Quarter - VIA PALERMO 74-76-78-80

Images ©2017 Google, Cartographic Data ©2017 Google

Description: The building is located in Via Palermo, on the opposite yard side adjacent to Via Brescia building, included in Sinfonia Project too. The buildings, built in 1960, are made up of several adjacent and articulated volumes and gather thirty-eight medium-large sized dwellings.

Ownership: IPES-WOBI Social Building Institute of the Autonomous Province of Bolzano

Gross volume: circa 13.038 m³

Gross Surface: 3.995,5 m²

Number of dwellings: 38

Energy performance:

Energy consumption excluded RES contribution

BEFORE

204,41 kWh/m² year (heating, domestic hot water and lighting)

AFTER

60,24 kWh/m² year (heating, domestic hot water, ventilation and lighting)

Energy consumption include RES contribution (Total Building Energy Use)

AFTER

46.41 kWh/m² year

Detailed characteristics of building

The architectural complex is articulated into 5 blocks comprising a basement and 4-6 floors above ground.

The accommodations, which have an average size of 85 square meters, are laid out on staggered floors and are served by 4 stairwells equipped with lift. Along via Palermo, the complex overlooks a private pedestrian area, partly used as a garden, while the backyard area is used as a parking lot and has two accessible carriages, one from via Palermo and one from Via Milano.

The interior of the block is characterized by the presence of a large park with tall trees and play areas.

Plot map

Image ©2017 Google, Cartographic Data ©2017 Google

Building envelope

The building has a reinforced concrete frame structure with brick tampons with a total thickness of about 36 cm. The pitched roof is made of a brick cladding, covered with metal sheet. The blinds have been partially replaced in relatively recent times and have different characteristics and materials. The shadings are made of plastic rolling shutters with internal bins.

Technical system

Most of the dwellings are equipped with gas boiler and heating system with radiators, some are heated with stove, other with electric heater. In some apartments, the electrical systems are not compliant with the current regulations.

Thermal image before refurbishment

©EURAC

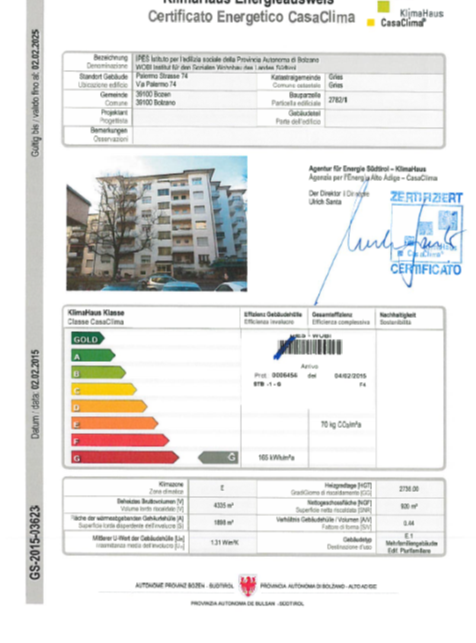

Energy performance certificate

Concept

The architectural project focuses on prefabrication, with the twofold objective of reducing the building time and thus the tenant's uneasiness.

The prefabricated "window" and "loggia" elements become the primary components to combine architectural and energy regeneration of the building. The "window" elements consist of a prefabricated wooden structure to be superimposed from the outside to the existing window compartment, adjusting the railing height to the current regulations (1.00 ml). Once the new items are mounted, the old fixtures will be removed, the ventilating machine installed and the interior finished.

The "window" element is made of wood-aluminium double glazed window, aluminium sliding blinds, decentralized mechanical ventilation components under the window sills, white extruded aluminium finish and the interior finish in plasterboard. The wooden prefabricated structure will be anchored to the existing sloping curbs and will create a column of overlapping elements that will act as a guide for laying the external pipework of the electrical system needed to feed ventilation machines from the outside.

The "loggia" element consists of an insulated wooden substructure to eliminate the thermal bridges, anchored to the existing slab and to the reinforced concrete pillars of the façade. The wooden structure and sheet metal design have been designed to divide the "loggia" elements into finished panels to be assembled on site. The use of colors (white alternating with red rust) makes it possible to reduce composite stiffness of existing building and give greater identity to the renovated building.

Energy Solutions

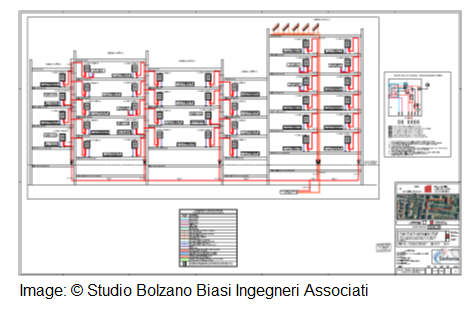

The target is to implement a centralized hydronic system that will replace all the existing devices.

The energy needs will be lower than 25 kWh/m² year; a solar thermal system will be installed, capable to meet at least 50% of the domestic hot water needs and a photovoltaic plant capable of producing at least 18500 kWh/yr. The buildings will be connected to the district heating network by a centralized sub-station, suited for about seventy dwellings.

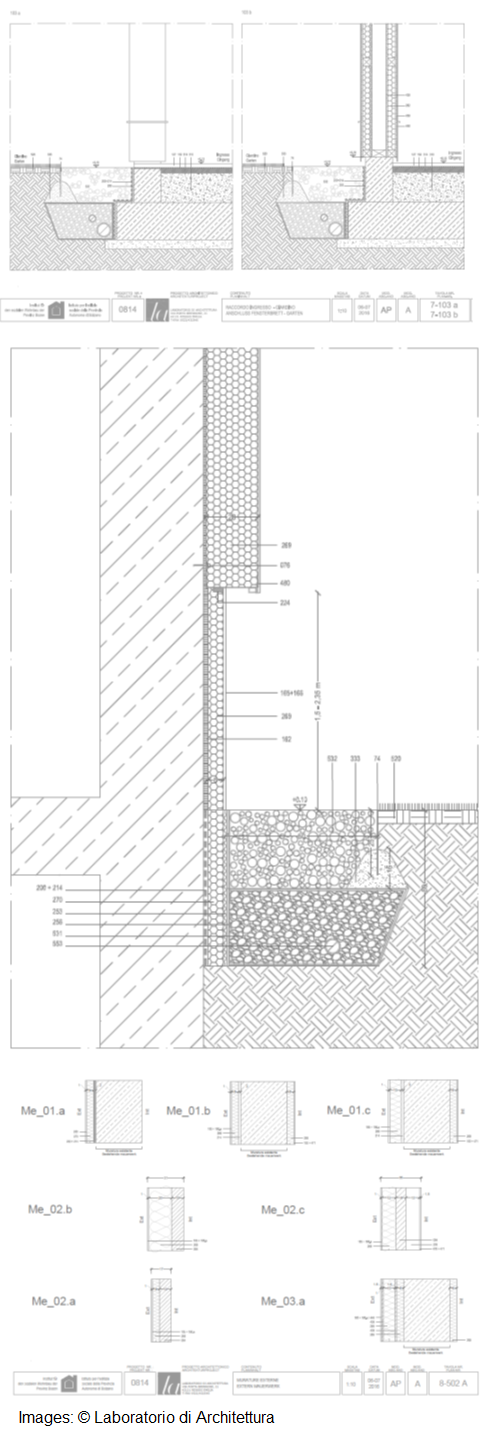

All the building will be insulated with a 20 cm thick polystyrene with graphite, with the exception of small portions under some loggias where the presence of windows near the corner involves laying a thickness of 12 cm. The basement, corresponding to the cellar plan, will be insulated with a 6 cm thick layer, which will extend under the ground up to about 60 cm deep. The cellars also will be insulated on the ceiling and on the exterior walls up to one meter from the ceiling with 6 cm thick expanded polystyrene.

Existing frames will be replaced with new ones, with wood-aluminium frames (Uf= 1.3 W/m²K) and double glazed argon (Ug= 1.1 W/m²K) with adjustable aluminium slats. The balconies will be equipped with vertical roller blinds for sunbathing. All living spaces except the bathrooms will be equipped with decentralized controlled ventilation under the windowsill.

The project involves the removal of existing roofing and the construction of a flat roof with a green roof, maintaining the balance of loads unchanged before and after the intervention.

The roof portions used for the installation of solar and photovoltaic panels will be realized with the green roof technology but the substrate (soil) will be replaced by gravel (maximum system water saturation weight not exceeding 100 kg/m²) to maintain the overall balance of loads unchanged.

Performances Targets

CasaClima A

Total Building Energy Use

46,41 kWh/m² year

Global Efficiency

14,71 kg CO2/m² year

RES contribution

55%

Financing Model

-

Envelope details:

Ground Attach (thermal bridge)

Technical system

Hot water distribution

Electric renewable integration

Building owner

IPES / WOBI

Architecture / Engineering

Laboratorio di Architettura

Contact

European Academy of Bozen/Bolzano (EURAC)