Powerhouse Rossau

Name and address

Wastewater treatment plant Innsbruck

Josef-Mayer-Nusser Weg 30

6020 Innsbruck

Austria

Map

Source; Google Maps

Type of installation

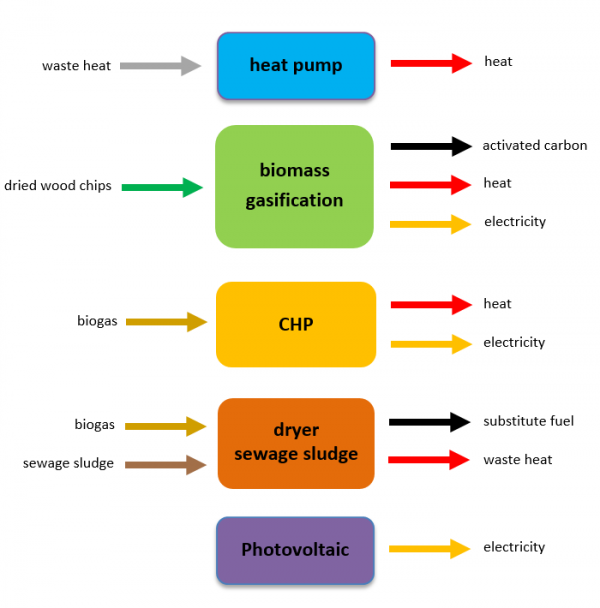

The RES-based energy potential at the site of Innsbruck wastewater treatment plant (WWTP) is used to generate heat, electricity, activated carbon and dried sewage sludge, which can be used as a substitute fuel. For this purpose, a smart combination of several components is necessary. The produced biogas, the accruing sludge of the WWTP, solid biomass wood chips and different types of waste heat are used as a primary energy source. The biogas is used in the CHP and in the hot water boiler of the sewage dryer, while the heat recovery is carried out by an air-to-water heat exchanger. The biomass gasification plant produces electricity, heat and activated carbon from wood chips. The energy derived from renewable sources is used for internal (WWTP) and external (public indoor swimming pool, restaurant at the public swimming lake, DH grid Innsbruck) consumers.

Ownership

Innsbrucker Kommunalbetriebe AG

Capacity

Biomass gasification plant

261 kWel / 393 kWth

Biogas CHP

1,702 kWel / 1,866 kWth

Biogas hot water boiler

1,800 kWth

Heat recovery – sewage sludge dryer

385 kWth

Façade integrated PV plant – biomass gasification plant

15,12 kWp

Conventional PV plant – biomass gasification plant

34,29 kWp

Conventional PV plant – public indoor swimming pool

18,72 kWp

Detailed characteristics of the device / infrastructure / service

The project “Powerhouse Rossau” includes the following major components:

- biogas-CHP,

- dryer for sewage sludge,

- biogas hot water boiler

- heat recovery - sewage sludge dryer

- biomass gasification plant,

- façade integrated photovoltaic plant

- conventional photovoltaic plant

- photovoltaic plant at public indoor swimming pool.

Concept

The figure below shows a simplified schematic representation of the project:

Technologies considered in the design

Biogas-CHP:

As part of Sinfonia, two new biogas CHP were installed at the wastewater treatment plant Innsbruck to convert biogas into electricity and heat. The plant has an electrical efficiency of 41 percent and a thermal efficiency of 45 percent, resulting in an overall efficiency of 86 percent. The electric power is 1,702 kW and the thermal power 1,866 kW.

Dryer for sewage sludge:

The implemented drying system reduces the sewage sludge mass by up to 75 percent, which in turn reduces the number of transport journeys and leads to considerable savings in CO2 emissions. The dryer is supplied by a biogas hot water boiler and the CHP's. Furthermore, the dryer is equipped with a highly efficient waste heat recovery system. The drying process produces around 4,000 tonnes of sludge granules per year with an energy potential of 13,000 MWh. The sludge granules can be used as a substitute fuel.

Biomass gasification plant:

In order to expand the supply of generating plants, an innovative demonstration plant for electricity and heat generation from renewable energies was realized. Local wood residues from forests and public parks are converted into wood gas, which is efficiently converted into electricity and heat in a combined heat and power plant. The heat is used as process heat for the wastewater treatment plant or transported to the nearby public indoor pool and the new restaurant on the public bathing lake. The by-product is activated carbon, which can be used in agriculture.

Conventional photovoltaic plant - public indoor swimming pool:

A photovoltaic system was built on the roof of the nearby public indoor swimming pool to cover a part of the own electricity consumption.

Façade integrated photovoltaic plant – biomass gasification plant:

A photovoltaic system was built on the building facade of the biomass gasification plant to cover a part of the own electricity consumption.

Conventional photovoltaic plant – biomass gasification plant:

A photovoltaic system was built on the roof of the of the biomass gasification plant to cover a part of the own electricity consumption.

Performance targets

- expected amount of produced heat: 21,662 MWh/a

- expected amount of produced electricity: 6,995 MWh/a

- expected amount of heat supply to DHG: 2,681 MWh/a

- expected amount of produced sludge granulate: 4.000 t/a

- expected amount of produced activated carbon: 1,348 t/a

- expected amount of reduced CO2: 11,440 t/a

Financing model

Direct investment of IKB 85%, national grant: 10 % and EC grant: 5%

Contracting authority

IKB Innsbrucker Kommunalbetriebe AG

Project manager

Sophia Neuner (IKB)

Manufacturer / supplier

Syncraft (biomass gasification plant)

Huber SE (sewage dryer)

GE Jenbacher (biogas engine)

Cost breakdown

The total investment costs are in order of 9.2 M€, Estimated payback time is: 10a

Implementation planning

1 - Design: 10/2014

Description of step: Planning and preparation of engineering

2 – Public procurement: 02/2016

Description of step: Procurement divided into 3 main parts

3 – Completion: 09/2017

Description of step: 3 phases of completion, test operation of 3 months

Work progress

Milestones

Figure 1: biomass gasification plant with façade integrated PV plant

Figure 2: district heating pipes from WWTP to public indoor swimming pool

Figure 3: PV plant at public indoor swimming pool

Figure 4: biogas CHP at the side of WWTP

Figure 5: sewage sludge dryer at the side of WWTP

Monitoring System

The entire system has a modern process control system, which connects all components with each other. All measured values required for operation are recorded in the system. In order to assess the performance of the individual components, KPIs are calculated.

Monitored variables and figures

The following data is recorded for the Sinfonia project:

- energy input and output [kWhel, kWhth]

- production of biogas [m3/h]

- reduction of CO2 [t/a]

Estimated lifetime

Biomass gasification plant: 20 yrs

Biogas CHP: 20 yrs

Biogas hot water boiler: 20 yrs

Sewage sludge dryer:20 yrs

PV plants: 20 yrs

Buildings: 50 yrs

Pipe systems: 20 yrs

Building owner

IKB Innsbrucker Kommunalbetriebe AG

Manufacturer/Supplier

Syncraft (biomass gasification plant)

Huber SE (sewage dryer)

GE Jenbacher (biogas engine)

Contact

Sophia Neuner (IKB)

Project Manager