District Heating Bolzano

Name and address

ALPERIA ECOPLUS

District Heating Bolzano

via Lungo Isarco destro 25

39100 Bolzano (Italy)

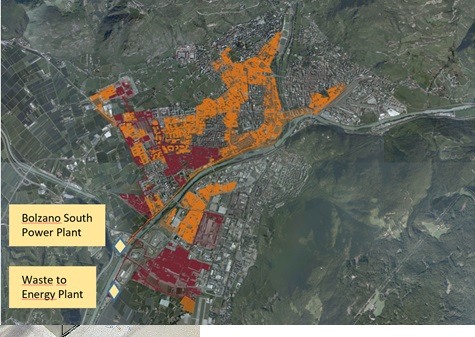

Map

Red – existing network; Orange – planned expansion

Description

ALPERIA ECOPLUS operates the district heating plant in Bolzano South and manages the district heating system of the City of Bolzano.

Bolzano’s existing DH system is composed by two generation units:

- Bolzano South thermal plant, which includes 2 combustion engines (natural gas) working in cogeneration mode and 5 boilers (natural gas and diesel).

- Waste to Energy plant with maximum capacity of 30 MWt and 10 MWe. The plant has just replaced the old incinerator and the large capacity is justified by the planned expansion project for the DH network.

Bolzano’s current DH network operates, as the majority of the Italian systems, at a temperature level ranging from 80 to 95 °C depending on the season.

Today the network provides heat to more than 200 users.

Ownership

ALPERIA ECOPLUS Srl

Via Dodiciville 8 – 39100 Bolzano

Ownership: 100% ALPERIA SPA

Technical details

Total installed capacity of thermal power: 39 MW

Current thermal energy production: 38.000 MWh/a

Gas boilers:

35,5 MW

26.000 MWh/a

NOx 114 mg/Nm³

Gas engines (CHP):

3,7 MW,th

3,6 MW,el

12.200 MWh/a heat

13.000 MWh/a electricity

NOx 234 mg/Nm³

Concept and energy solutions

1. In Bolzano, Alperia has been responsible for testing a more sustainable supply system for one of the two existing cogeneration engines in Alperia Ecoplus' district heating plant (Task 8.4.1 Smart cogeneration plant: emission reduction by using innovative gas blends): the engines have been prepared and converted for the use of methane/hydrogen blends.

2. Alperia has also been responsible for introducing an intelligent and innovative control system for the optimal operation of the extended district heating network (Task 8.4.2: Forecast and prevent heat and cool peaks demands in the DH/C network).

Performance targets

Task 8.4.1: Emissions reduction

Task 8.4.2: Enhancement of the distribution efficiency and reduction of energy losses.

Financing model

50% EU co-financing (SINFONIA)

50% own funds

Stakeholders involved

Contracting authority: Alperia Ecoplus Srl

Project managers: Stephan Hasse, Alessandro Mazzocato, Giorgio Dalvit

Technical system designer: ITB (Ingenieurteam Bergmeister GmbH)

Manufacturer / supplier: Linde Gas Italia Srl; INNIO Jenbacher GmbH & Co OG; IIT (Institut für Innovative Technologien GmbH); FER Strumenti srl; PETROL d.d. Ljubliana

Other involved companies: Eco-Research srl; Danfoss Ges.m.b.H

Costs

Cost breakdown

Task 8.4.1: 314.838,30 €

Task 8.4.2: 157.486,75 €

(as reported in the official Hand Over Certificates)

Description of the works

Activity: Modification of one of the 2 gas engines, situated in the combined heat and power plant of Alperia Ecoplus at Bolzano, for the use of methane/hydrogen blends (Task 8.4.1)

Site Location: Teleriscaldamento Bolzano, Lungo Isarco Destro 25, 39100 Bolzano

Dates

Start Dates:

17.07.2015 ITB (risk assessment, assistance with authorizations, security coordination in the planning, final/construction, design hydrogen engine)

21.10.2016 FER Strumenti (supply and installation of a CO2 sensor and a CH4 sensor for measurement of emission)

11.05.2017 Linde Gas Italia (H2-piping, automatisation, safety measures, hydrogen transport)

11.05.2017 INNIO Jenbacher (modification of the existing gas engine for the use of methane/hydrogen blends)

24.08.2017 Eco-Research (within "supply and installation of a CO2 sensor and a CH4 sensor for measurement of emissions": Check of linearity of the Automated Measuring System (AMS) according to EN 14181:2015)

28.08.2017 IIT (production and supply of green hydrogen)

Completion Date: 02.07.2018 (communication of completion of work to the Municipality of Bolzano)

Activity: Modification and adaptation of controls to forecast and prevent the peak heat load formation and to optimize DH temperature supply (Task 8.4.2)

Site Location: Bolzano (Italy)

Start Date: 08th March 2016 (Kick off meeting)

Completion Date:31/12/2019 (End S&U phase)

Description of activities performed / Technical specifications:

- Analysis of how different operation strategies might affect DH users;

- Offline DH model creation and validation;

- Installation of sensors along the DH network;

- Update the architectural scheme of Alperia IT network;

- Real time DH model creation and calibration;

- District heating temperature supply optimization

Work progress

Task 8.4.1

Before conversion, the combined heat and power plant (CHP) was operated solely with combustion of natural gas (NG). Emissions are recorded using continuously a Continuous Measurement System (CEMS). All limit values for emissions were within the legally required specifications.

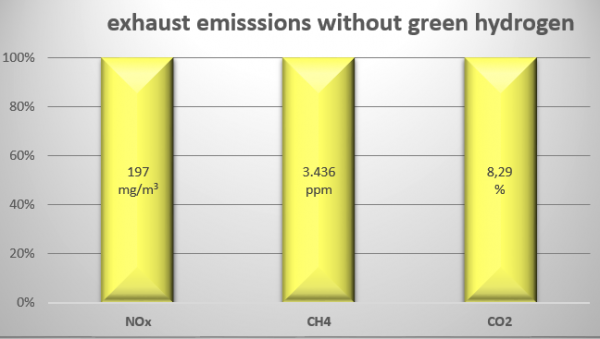

Figure: Initial situation: Operation of the CHP-plant with natural gas

Modifications of the engine (turbocharger, motor valves, combustion control).

The green hydrogen production took place in the H2 Center South Tyrol in Bolzano and was transported in special trailers to the 4 km distant district heating plant.

Figures: Modifications for the use of hydrogen

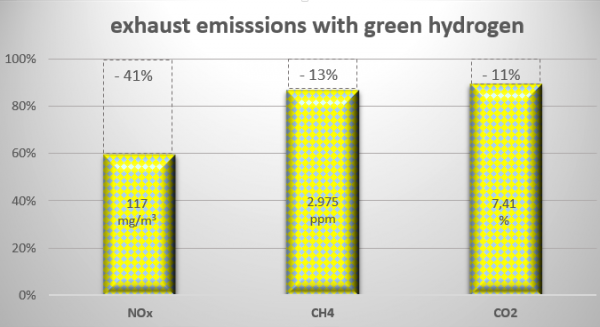

The hydrogen admixture to natural gas was carried out up to a volume of 30%.

Results show a significant reduction of air pollutants, especially of nitrogen oxides.

Figure: Operation of the CHP-plant with H2/natural gas mixture

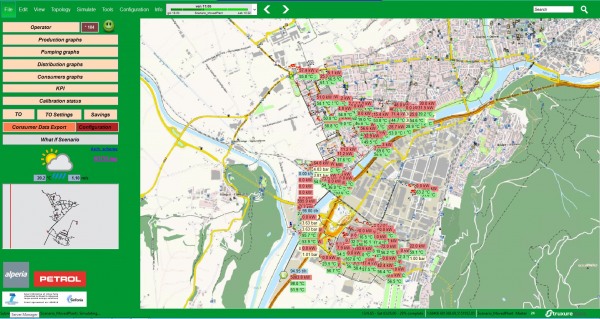

Task 8.4.2

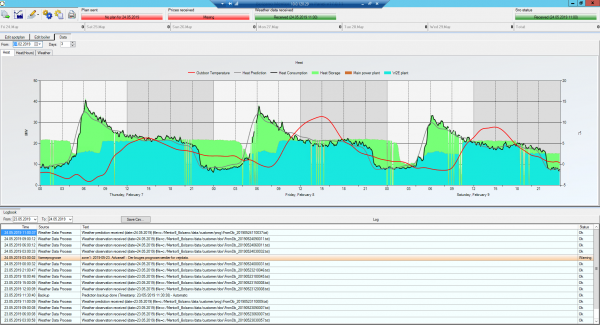

Figure: Real time monitoring

Figure: Heat load forecasting tool

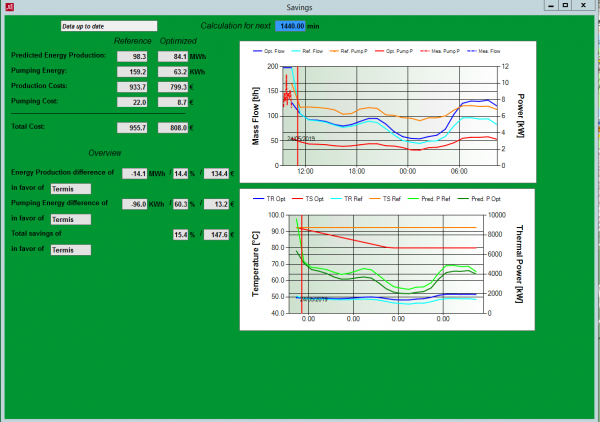

Figure: Temperature optimisation tool

Monitoring results

1. Task 8.4.1 Smart cogeneration plant: emission reduction by using innovative gas blends: with a hydrogen additive of up to 30 percent by volume, Alperia has reduced carbon dioxide emissions by up to 15 percent and nitrogen oxide emissions by up to 40 percent.

2. Task 8.4.2: Forecast and prevent heat and cool peaks demands in the DH/C network: with this advanced control system, the district heating of Bolzano can now operate with maximum distribution efficiency and energy losses in the entire network can be reduced by up to 5%.

Owner

ALPERIA ECOPLUS Srl

Via Dodiciville 8 – 39100 Bolzano

Ownership: 100% ALPERIA SPA

Contact

European Academy of Bozen/Bolzano (EURAC)